Our Workflow

01

Send available 3D or 2D files and detail request .Such as material ,finish ,quantity . our engineer team will contact you soon .

02

Analyse design and verify machining program via MasterCAM software . according to CNC machining time , complexity, tolerance etc send back you official quotation .

03

Singed the contract ,estimate order processing schedule . we will upgrad the project status weekly .

04

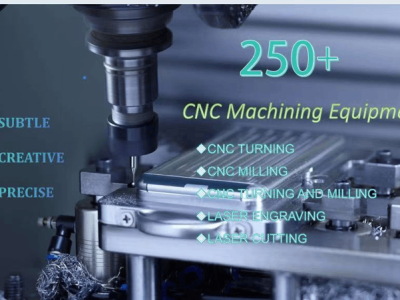

To start Our factory has 250 sets high precious 3.4.5 axis CNC center . 3-5days for the prototype , 300000piece monthly . Tolerance is less±0.02MM. available material :aluminium ,stainless steel ,titanium ,plastic.

05

Various surface treatment can support . Polish ,brush ,Anodized ,UV Anodized , powder coating , Oil Spraying, eletroplating and PFA coating . it also support customization color basic RAL and pantone number .

06

Full Dimension Inspection All of the product passed 5 times QC inspection .it make sure all of the product will be good quality . Raw Material Inspection First Part Inspection In-Process Inspection Final Inspection Outgoing Ins pection Report

07

Package & deliver Accept the OEM package ,pattern,Logo . and choice economic shipment way . Take the detail pictures of the product and package .dimension inspection report also will be ship together .

08

No -worries after purchase Reqular follow-up the Customers Experience,Record the client feed backand solve it timely,Free replacement service in necessity.